The L7 industrial flaw detection film is developed according to high starting points and high standards, and adopts a series of new technologies from emulsion synthesis to coating process

Technology and new materials are ideal films for industrial radiographic testing.

Lucky Industrial X-ray Film L7 is produced by China Lucky Film Corp.lis designed in accordance with advanced standardA series of new materials

And technology is being used from emission - making to coating It is an ideal film for industrial non destructive inspection photography

FEATURES AND USAGES

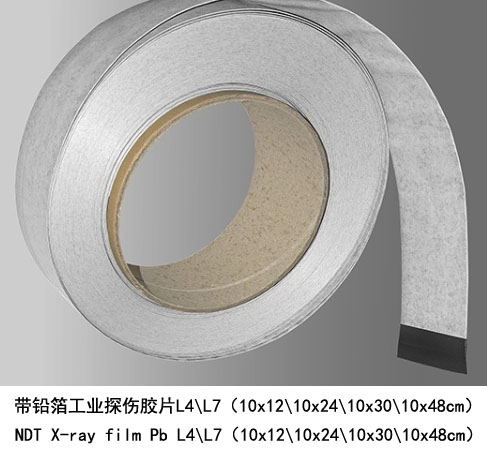

Lekai L7 industrial film uses a blue polyester film base as the support, and is coated with a photosensitive emulsion film on both sides. It belongs to the film type with fast ray sensitivity, micro particles, and high contrast. Its fine silver halide crystal

The particles and their good distribution state, as well as the specially treated photosensitive coating and reasonable coating structure, endow them with the ability to distinguish defects with high quality. Widely used for ferrous metals, non-ferrous metals and their alloys, or others

Non destructive X-ray testing of devices, profiles, parts, or welds made of materials with smaller decay coefficients.

Lucky Industrial X-ray Film L7 is doublecoated on blue polyether baseIt is high speed with

Small grain and high contrast. It has perfect ability to find the defect exactly because of its excel

Structure of emission grain and coating layer. It is widely used in non destructive X-ray inspection

For parts, components, shaped materials or welding seams made of ferrous, non ferrous metals anc

Their alloys or other materials with low attention coefficient

SAFE ILLUMINATION

This product can be used as a safety lighting lamp for processing or inspection using Lucky LZ-2 or Kodak No-2 dark red safety lamps with a transmittance range greater than 630nm, or other similar lamps. The 15 watt bulb should be at least 1.2 meters away from the film

Far away.

This film can be processed and inspected under dark red safelight Filter of Lucky LZ-2 or KodakNo. 2 or other equivalent filters with transitioning range over 630nm A 15W safe-lamp should keep 1.2 meter away from the film

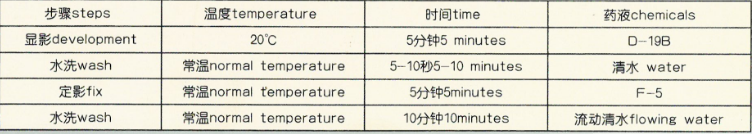

Flushing Processing

The process for developing and processing Lekai L7 industrial film can be either manual processing at room temperature or machine processing at high temperature. The recommended process conditions for manual processing at room temperature are as follows

Lucky Industrial X-ray Film L7 is compatible with variable processing machines and it car processed by hand in normal temperature as the following conditions

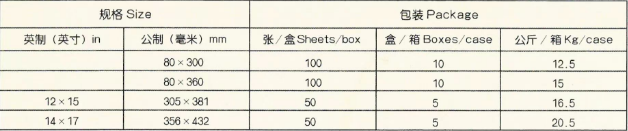

Specification packaging:

Precautions REMARK

Unexposed films should be stored in their original packaging in a clean, dust-free, ammonia free, hydrogen sulfide free, and radiation free area. Dampness and heat have adverse effects on the film. It is recommended to store in an environment with a temperature below 21 ℃ and a humidity below 65% RH. For unsealed film, the ideal storage humidity is 30% RH-50% RH

Unexposed film should be kept in original packages and stored in places where it should be clean, no dust, free from ammonia hydrogen gases and penetrating radiation. The film is adaptively affected by heat and humidity. The computational storage temperature is below 21 ℃ and humidity below 65% RH. For unsealed film The ideal humidity is from 30% RH-50% RH

Packaging film should be placed vertically to avoid indentation on the film

The film packages should be placed on edge to avoid pressure marking the film

When using films stored at low temperatures, they should be taken out in advance and left at room temperature for more than 4 hours before opening the packaging for use to avoid damage to the film surface caused by condensation of water vapor.

The film stored at low temperature should be conditioned at room temperature for more than 4 hours before opening the package for using in order to prevent condensation on the film surface and degradation of the film

The photographic performance of the film varies with storage time and should be used within the warranty period. The exposed film should be developed and processed as soon as possible.

The photographic properties may change during age, there before the film should be used in a warranty period The

Exposed film should be processed an soon as possible

The film should be handled carefully to avoid physical damage caused by compression, folding, twisting, and friction. It is also important to be very careful not to touch the film with wet hands before and after processing.

The film should be handled carefully to avoid physical strands caused by pressure creating, buffering and friction. High attention must be paid not to touch or grasp the film with wet hands before and after processing